COMPANY OVERVIEW

-

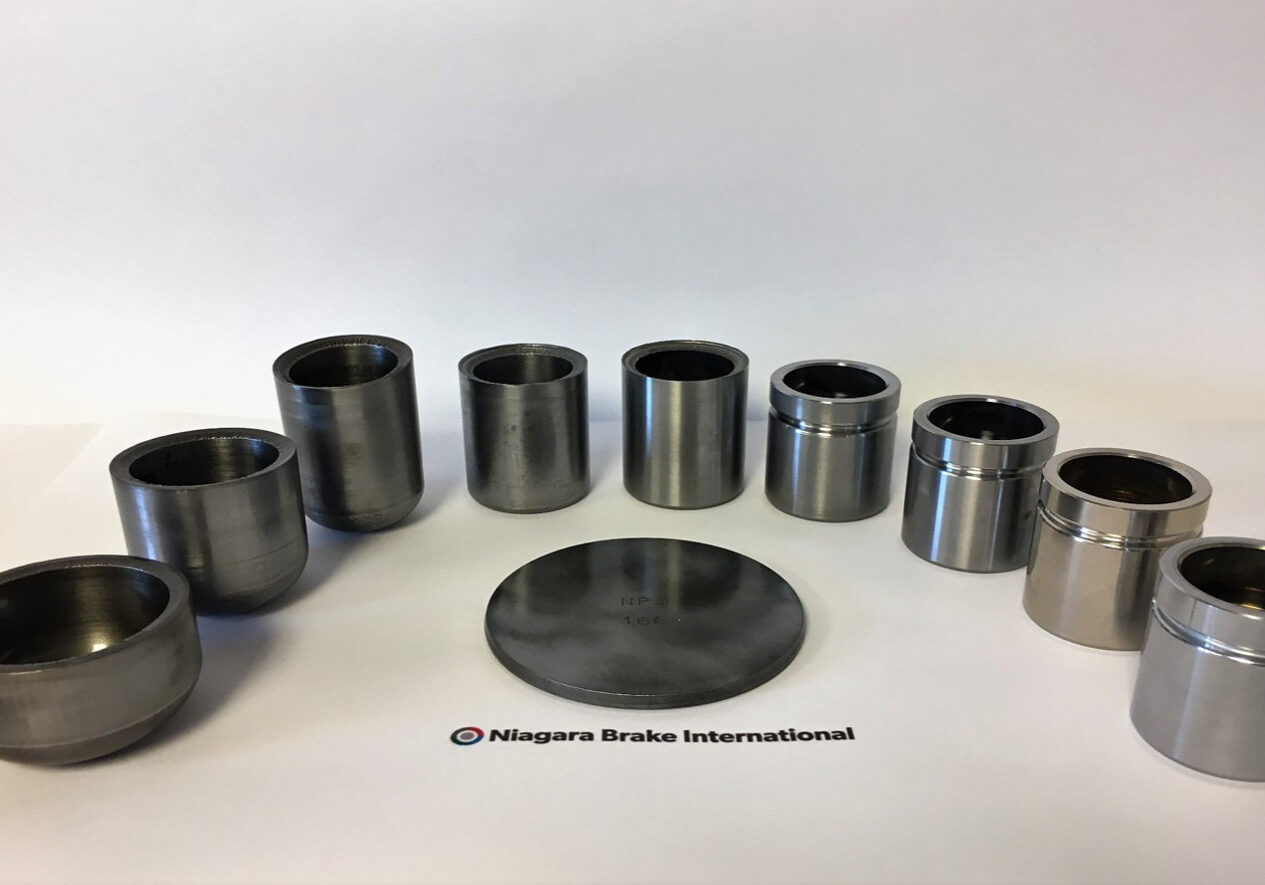

Niagara Brake International is a leading global producer of OEM disc brake caliper pistons in the world. Founded in the NAFTA region, over the past 30 years we’ve grown our footprint globally and now serve a diverse, worldwide customer base. We’re proud to stand alone in the industry as the only manufacturer to specialize in both steel and phenolic products as well as our ability to completely form, machine, grind and plate our pistons under one roof.

-

We’re innovators and problem solvers, helping the world’s best brake manufacturers respond to their customers’ demands for safety, quality and value. We manufacture our pistons from the steel blank or phenolic compound right through to the finished product, maintaining complete control over the process for optimum quality, efficiency, cost-effectiveness and environmental responsibility. This optimized production process has allowed us to achieve an industry-lowest PPM defective rate and helps solidify our position as the first choice of Tier 1 companies.

-

Our people make our processes work. Their commitment to our values means we can be a global giant with the mindset of a small company a flexible, ethical, innovative and responsive partner that can fill your biggest order and satisfy your most demanding customer on a timeline and at a price our competition just can’t meet. Niagara Brake Int.'s impressive growth is because of the unique culture and product specialization at each of our plants and that’s why we want to be the best employer we can be.

-

Products, processes and people. Three very important reasons why, whether it’s for everyday commuting, weekend performance or working with a full-size pickup, it’s probably a Niagara Brake International piston that’s putting the brakes on and saving lives.

OUR HISTORY

1919: Company Started In Ontario, Canada.

- Original business was electric arc welding

1930: Company expands into Metal Finishing

- Chrome plating

1956: Succession to Second Generation

1985: Open New Facility Niagara Piston Inc.

- Manufacture of Brake Caliper Pistons

1993: Niagara Piston Inc.

- Expands Facility to increase production

1994: New Facility

- Maple Manufacturing of Steel Brake Pistons

2002: Succession to Third Generation

2008: Acquisition of Diemolding

- Located in USA for Manufacture of Phenolic Brake Pistons

2011: Acquisition of Finotex

- Located in India for Manufacture of after Market Brake Pistons

2011: New Facility Niagara Piston Bartlett

- Manufacture of Phenolic Brake Pistons

- Located in Canada

2016: New Facility Start Up in Nantong China

- Manufacture of Phenolic Brake Pistons

2018: Niagara Brake Products (Nantong)

- OEM SOP

MANUFACTURING FACILITIES

- 3 facilities in Ontario, Canada

- Leading producer of steel disc brake pistons in North America

- Only company worldwide producing OEM steel & phenolic pistons

- Capacity of 26.0 million Steel and 20.0 million Phenolic Pistons per year

- 1 facility in New York state, USA

- Largest producer of phenolic disc brake pistons worldwide

- Capacity 32.0 million Phenolic Pistons per year

- 1 facility in Nasik, India

- Largest fully integrated phenolic disc brake piston manufacturer in India

- Capacity of 2.0 million Phenolic Disc Brake Pistons per year

- Fully integrated phenolic disc brake piston manufactured in China

- Launched 2018

OUR VALUES

PHENOLIC PISTON

MANUFACTURING PROCESS

-

Phenolic Molding Compound

-

Pre-form

-

Pre-Heat

-

Mold

-

Manual DeFlash

-

Auto DeFlash, Inspect & Laser Etch

-

Bake

-

CNC Machine, Grind , Auto and Visual Inspection

-

Pack

STEEL PISTON MANUFACTURING PROCESS

-

Steel Blank

-

Deep Draw

-

Rough grind

-

CNC Machine

-

Finish grind

-

Ni Plate

-

Cr Plate

-

Auto & Visual Inspection

-

Pack

Steel Pistons

Phenolic Pistons

Total Pistons

AUTOMOTIVE INDUSTRY CUSTOMERS

Supplying the automotive industry for the past 100 years

Ford Logo

FCA Fiat Chrysler Logo

GM logo

Lexus logo

Hyundai logo

Mercedes logo

Mazda logo

VW logo

Peugeot logo

Nissan logo

Toyota logo